We have a graphite shortage. We need millions of tons of this critical material to build batteries for electric vehicles, power grids, and electronics, yet we haven’t mined natural graphite domestically since 1990. Meanwhile, China produces approximately 70% of the world’s natural graphite and 60% of synthetic graphite, leaving western manufacturers vulnerable to supply chain disruptions and price volatility.

But scientists at the Department of Energy’s National Energy Technology Laboratory (NETL) have developed an elegant solution that addresses two problems at once: transforming coal waste and discarded plastics into battery-grade graphite.

A Revolutionary Process

The breakthrough centers on a simple but powerful innovation: using common catalysts like iron to convert waste materials into highly crystalline graphite. What makes this process remarkable isn’t just what it produces, but how efficiently it works.

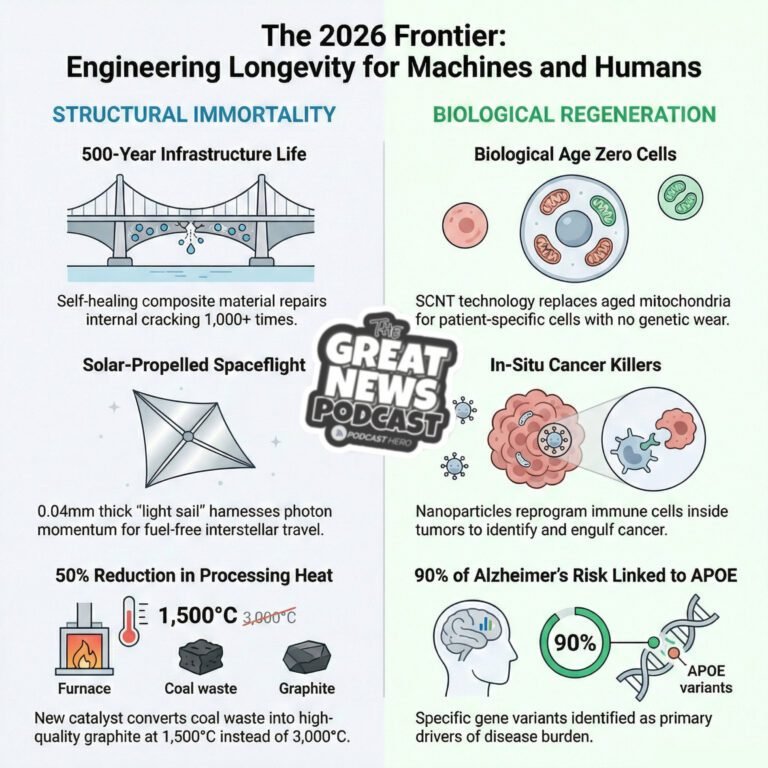

Traditional graphite manufacturing requires extreme conditions. The NETL catalyst drops process temperatures from 3,000 degrees Celsius to less than 1,500 degrees Celsius and reduces processing times from several weeks to just a few hours. Lower temperatures mean less energy consumption and lower costs—critical factors for commercial viability.

Even better, the catalyst can be recovered, recycled, and reused indefinitely, further improving the economics while reducing environmental impact.

From Waste to High-Performance Materials

The process accepts a remarkably diverse range of feedstocks. Coal of different ranks, coal waste, coal char, bio-char, petroleum coke, and plastic waste have all been demonstrated to work. This flexibility is crucial—it means the technology can adapt to whatever waste streams are locally available, from abandoned coal piles to single-use water bottles.

Performance testing has validated the quality of the resulting material. Graphite produced with this process has been tested as a battery anode and has been shown to outperform anodes made with commercially sourced graphite materials.

The Scale of the Opportunity

The timing couldn’t be better. Demand for graphite is expected to increase by more than 2,000% between now and 2040 due to the electric vehicle revolution and renewable energy storage needs.

Ki-Joong Kim, the principal investigator on the project, sees enormous potential: the technology could establish a new domestic manufacturing base for this critical material and serve as a valuable asset in the American economy at a time when new graphite sources are urgently needed.

What Comes Next

NETL has already secured additional funding through the DOE Critical Materials Innovation Hub to expand this research, partnering with Oak Ridge National Laboratory, Ames National Laboratory, and private industry to scale up the technology.

The vision is compelling: rather than shipping waste to landfills or relying on foreign suppliers for critical materials, we could build a domestic graphite industry that turns our trash into the building blocks of clean energy technology. It’s the kind of circular economy solution that addresses environmental challenges while strengthening economic and national security.

Sometimes the most powerful innovations come from seeing waste not as a problem to dispose of, but as a resource waiting to be unlocked.

This topic was covered in Great News podcast episode 28

Sources: Interesting Engineering, National Energy Technology Laboratory